Quality. Standards. Verified.

Quality management

and assurance

When dealing with challenging parts and components, which we manufacture every day, the level of quality assurance must always meet these highest standards. That is why we have implemented specific measures and processes in order to ensure that our CNC machined parts and components meet our high standards of quality. It is our main objective to manufacture parts free of defects and precisely to the specifications and requirements defined by our customers. It is our philosophy to meet the highest level of customer satisfaction.

Contact us if you would like to learn more about

why we are more committed to quality assurance than the competition.

Quality management

Our quality management program is ISO 9001 certified and of course gets audited and re-certified every three years. Within the first two years of the validity period of the certification, our processes are being monitored by audits done by external auditors. In addition to that, we conduct internal audits for products and processes in order to constantly monitor and continuously improve. This is how we ensure consistent quality and the re-traceability on each of our on-time deliveries.

Quality assurance

Incoming goods inspection

Reliable quality assurance begins with the inspection of the incoming materials. These verifications are conducted to ensure that the delivered materials are meeting the required quality standards and thus, are suitable for the CNC manufacturing processes and finishing (where applicable).

Measurements and inspections during the manufacturing process

Our qualified employees conduct multiple measurements and quality checks during the CNC machining process in order to ensure our parts and components meet the specifications and tolerances required. Besides the pre-defined testing schedules, we conduct visual inspections and constantly monitor the machine parameters.

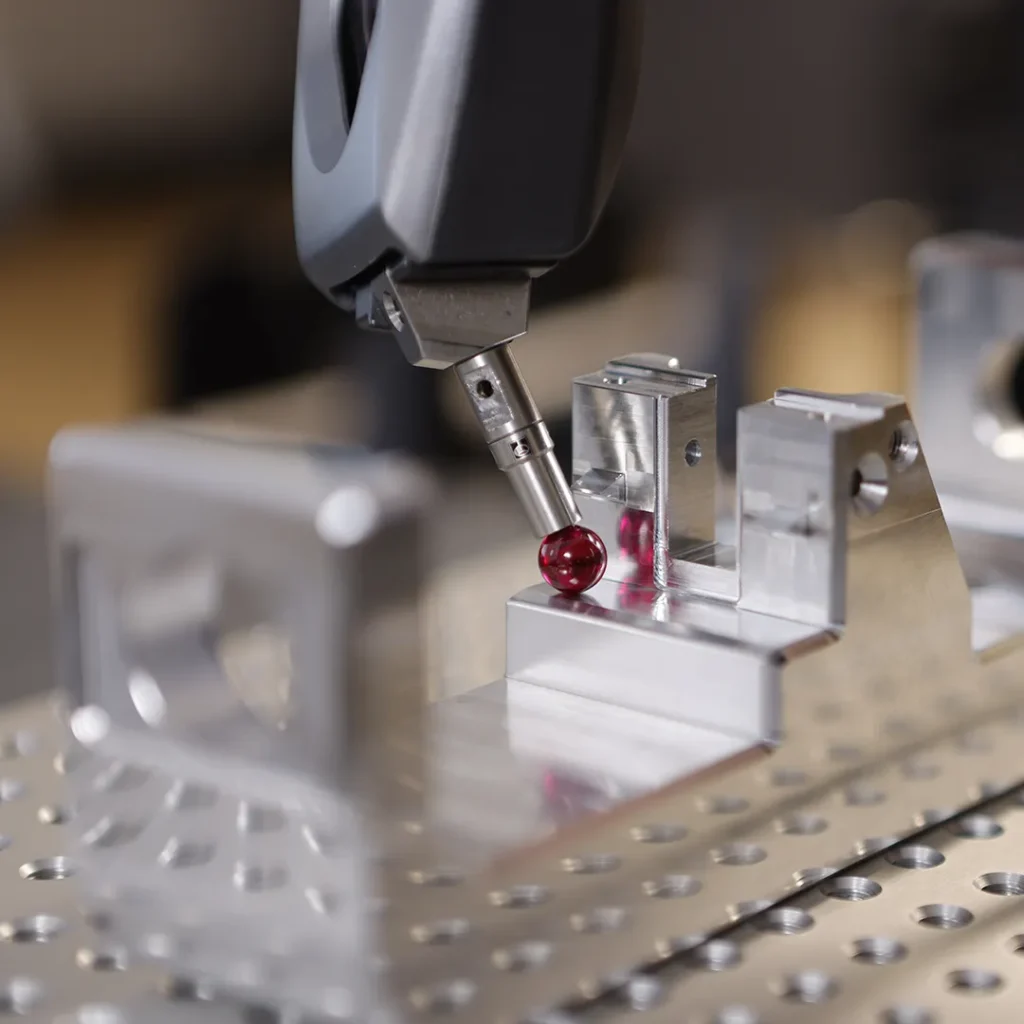

Testing devices

We only use high-quality measuring equipment and gauges for our in-process testing. At our disposal are a wide range of hand-measuring equipment, as well as roughness measuring instruments and a 3-D coordinate measuring device. All of our testing equipment is being tested and calibrated at regular intervals and by accredited laboratories.

Finished/ outgoing goods inspections

Before any customer order leaves our facilities, it will be subject to a final inspection. After the parts and components are being inspected following customer-specific requirements, they are packaged and shipped out.

Documentation and traceability

All relevant data and information about the parts made by us are meticulously documented in order to provide retraceability of every customer order. This approach enables us to identify potential problems as well as the tracking of parts in case of quality issues or recalls.

Declarations of conformity

As a company that operates at a very high level of due diligence, we also issue certain declarations of conformity. Upon customer request and where applicable, we confirm the conformity of the materials used in regard to the rules and regulations of REACH, RoHS, Prop65, Conflict Minerals etc.

German Supply Chain Due Diligence Act

This law was enacted on January 1st, 2023. It legally binds companies with at least 3.000 employees to comply with human rights standards and environmental regulations in their entire supply chains. On January 1st, 2024, the threshold will be lowered to companies with at least 1.000 employees. Even though GDFT is not bound by this law, we are still part of the supply chain and therefore voluntarily comply by being transparent when it comes to raw materials, purchased parts or services rendered by our suppliers.

You can expect GDFT to follow these specific steps when realizing your project

- Incoming goods inspections

- Close and frequent measurements and inspections during the manufacturing process

- Modern testing equipment and measuring devices

- Warenausgangsprüfung vor dem Versand

- Complete documentation and traceability

- Declarations of conformity

- Voluntary compliance with the German Supply Chain Due Diligence Act

GDFT highly values the quality of raw materials and purchased parts.

Do you share this vision?