Clean room. ISO. Class 8.

Clean

room

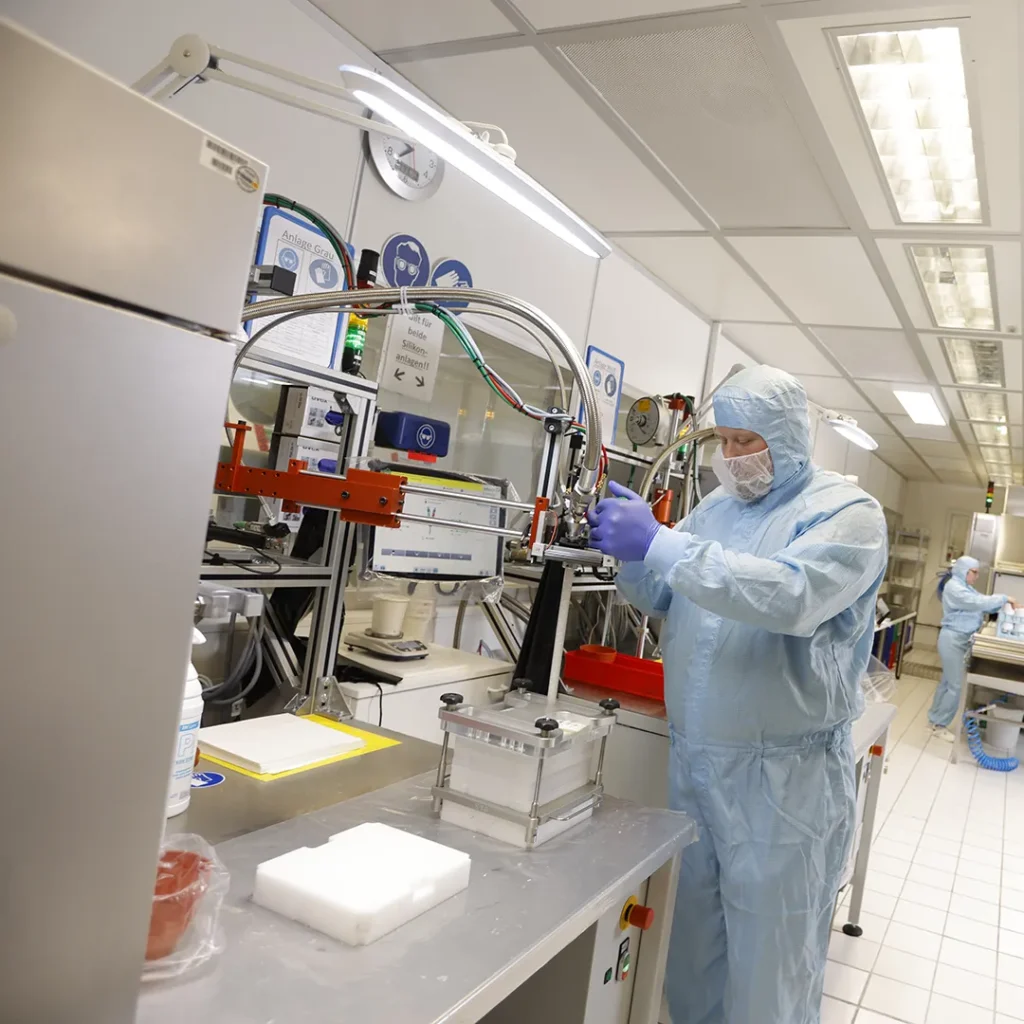

At GDFT we operate a certified clean room of class 8 in accordance with the ISO-14644-1 standard. A certification per GMP guidelines has not been obtained, as none of our customers has asked for one. Our hygiene concept however, strictly follows the GMP practices and guidelines.

Contact us if you would like to learn more about our clean room capabilities and whether we can manufacture your parts and components in our clean room.

Measures and inspections

The air-quality management in our clean room is being achieved by the deployment of special filtration and ventilation systems. Employees that operate in the clean room are especially trained and wear appropriate protective clothing in order to minimize any contamination. Before reaching the clean room, all staff must pass through an air lock, which minimizes outside particles reaching the inside area and the materials. The materials are being fed into the clean room through a separate air lock for processing.

Manufacturing process inside the clean room

Currently there are two processing steps: PP pipes are being fed through a basket washing machine and are vacuum sealed afterwards. This enables our customers to use these parts and components in their clean room for further processing immediately.

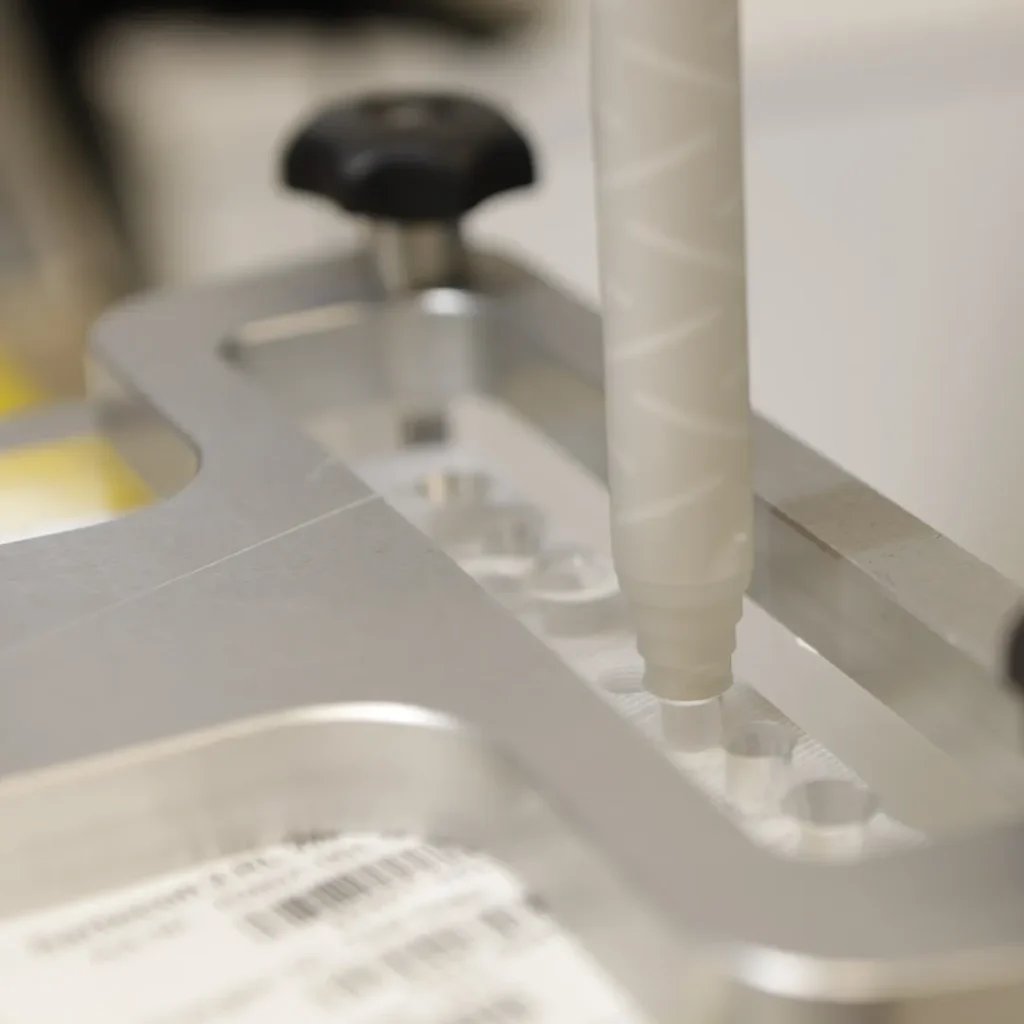

In a second step, silicone is being dispensed onto fiber matting and cured in drying chambers per specific parameters. After curing the silicone mats are being packaged to the customer’s requirements. Thus, the silicone can also be used in the customer’s clean room for further processing – no extra steps required.

Overview: Your advantages for manufacturing in a clean room setting:

- Clean room in accordance with ISO-class 8 (DIN EN ISO 14644-1-Norm) – meaning less than 3.520.000 particles per cubic meter, maximum particle size: 0.5 microns

- Specially trained clean room personnel

- Strict hygiene rules and regulations throughout the entire manufacturing process

- Staff must wear protective clothing and gear

- Separate air locks for staff and product as controlled entry points

- Close monitoring of air temperature, humidity and other parameters

- Frequent and scheduled cleaning and maintenance cycles throughout the entire production line

- State-of-the-art filtration equipment for the removal of suspended particles

- Lückenlose Dokumentation der Fertigungsprozesse

Would you like to know more about our ISO-certified clean room?