customized solutions

we love

When it comes to machining different types of materials, we are the experts.

Göttinger Dreh- und Frästeile GmbH specializes in the efficient and precise manufacturing of singular parts, components and modules, utilizing the processes of CNC-lathe turning and CNC-milling.

At our shop – everything revolves around the production of the highest quality parts.

You will need a contracted manufacturer

for CNC lathe turning or CNC milling, if…

- you do not own you the required equipment;

- you have material- or machine-related bottlenecks within your own manufacturing setup;

- when the parts you want to produce are too complex for your resources;

- if you do not possess the know-how and would rather use a specialist;

- you want to focus on other areas of your business;

- if it is just more economical for you to outsource.

Do you find

yourself here?

Trust throughout the entire production-process

INDUSTRIES

Utilizing state-of-the-art machine equipment and a highly experienced team, we provide solutions for advanced and universal requirements. Next to highest quality standards, GDFT prioritizes flexibility, individual solutions, fast delivery times as well as straightforward service to our customers.

Our portfolio includes a wide variety of projects realized for well-known companies from, for example, laboratory technology-, optics industries- and mechanical engineering backgrounds.

Medical/Laboratory

Whether it may be enclosures for lab equipment, sample holders or precision parts for measuring devices – the requirements for quality and precision in the laboratory and medical industries are extremely high. We are up for the challenge.

Optics industries

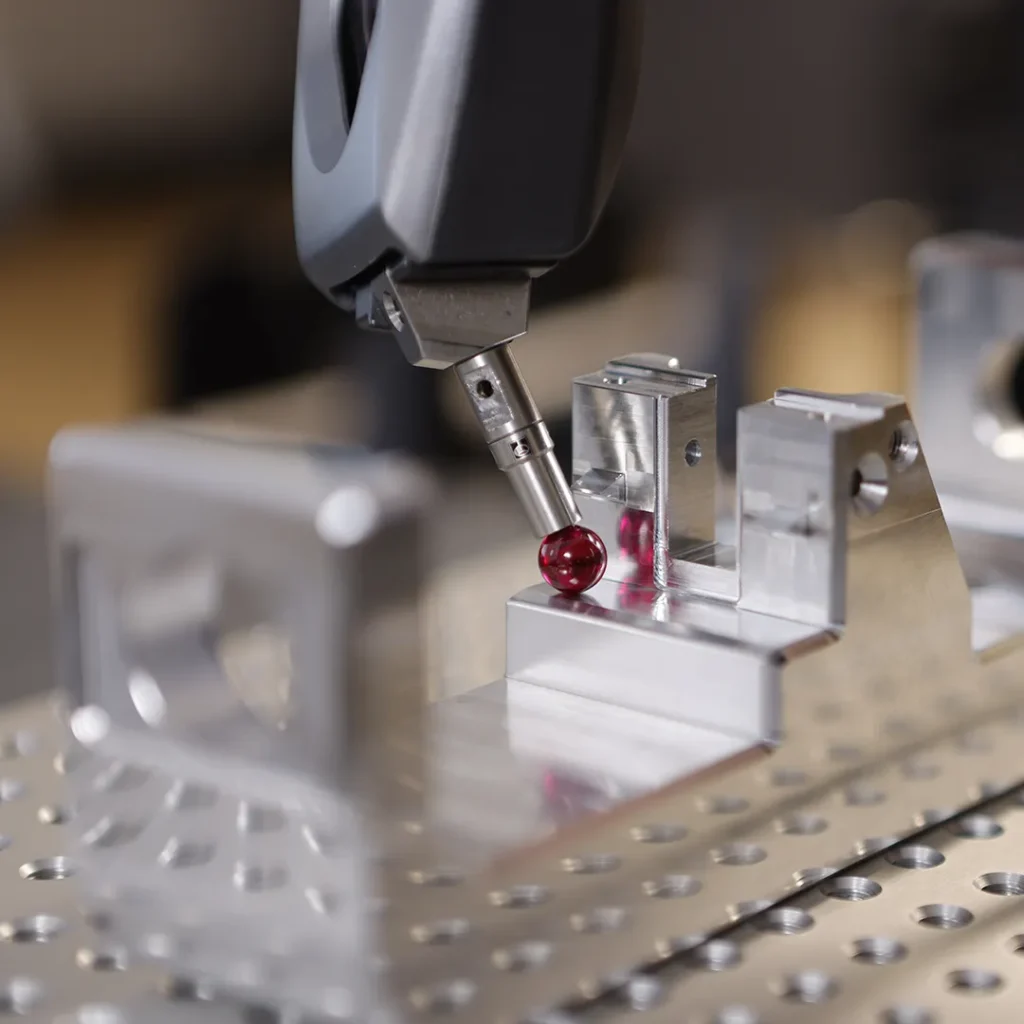

Companies in the optics business require very precise parts and modules. These components must be of high accuracy in terms of shapes, dimensions as well as surface characteristics.

Mechanical engineering

With our wide range of machine equipment, we can produce as well as assemble a variety of parts and components for the mechanical engineering industry. It does not matter whether you need prototypes, small batches, or large-scale production parts.

Cannot find your industry here? Then get an individual consultation now.

High-precision machinery

When your (3-D) model arrives here, it will embark on an exciting journey.

CNC turning

manufacturing

Cylinders. Perfectly. Turned.

When it comes to the manufacture of cylindrical parts, you can rely on the capabilities of a CNC lathe. Through the fast-turning of the parts, curvature- and diameter requirements can be precisely achieved.

CNC milling

manufacturing

Shapes. Precisely. Milled.

The high-precision process of a CNC milling machine allows for a cost- and time-efficient manufacturing process – even when dealing with complex components. With our 3- or 5-dimensional milling equipment and a wide range of milling tools, we produce quality that you can see and feel.

Module assembly

manufacturing

Modules and components. Custom-fit. Assembled.

Besides the manufacturing of parts, we also provide the assembly of entire modules – even when the process requires components made from different materials. We even provide the necessary logistics to you. The assembly of the different parts required for the final products is done by us, in-house and always adhering to highest quality standards.

Finishing

manufacturing

Components. High-quality. Finished.

After the manufacturing parts using our CNC milling or CNC lathe turning equipment, the components can undergo optional finishing processes, such as sanding, polishing, coating or annealing. Take advantage of a wide range of finishing techniques in order to make your final product more durable or aesthetically appealing.

Materials

manufacturing

Materials. Efficiently. Processed.

Using CNC machining, a wide range of materials can be transformed into parts and components. We have specialized our machining equipment to transform metals as well as synthetic materials.

End-to-end solutions

SERVICE

Processes. Optimal. Organized.

From consulting to logistics – we provide it all in-house, including know-how, experience and professional expertise – every step of the manufacturing process. You will have only one point of contact – from production all the way to shipping your orders.

What makes a good contract manufacturer?

6 ARGUMENTS TO BE MADE FORE THE GÖTTINGER DREH- UND FRÄSTEILE GMBH

1

Our Know-how

Extensive experience in processing materials, programming and the utilization of CNC-equipment

2

Our standard of quality

Our highly trained staff always focuses on the accuracy of our tools and machine equipment

3

Our flexibility

With a wide variety of materials and ways to transform them – we are ready for any challenge

4

Our efficiency

With highly efficient process planning of materials, equipment and manufacturing capacities, we can deliver fast – all over the world.

5

Our price-performance ratio

We manufacture precision turned and milling parts and components with a focus on fairness and cost-transparency.

6

Our promise

We support our customers and their efforts by engaging in close communication and by providing comprehensive services