A. to. Z.

Industries

overview

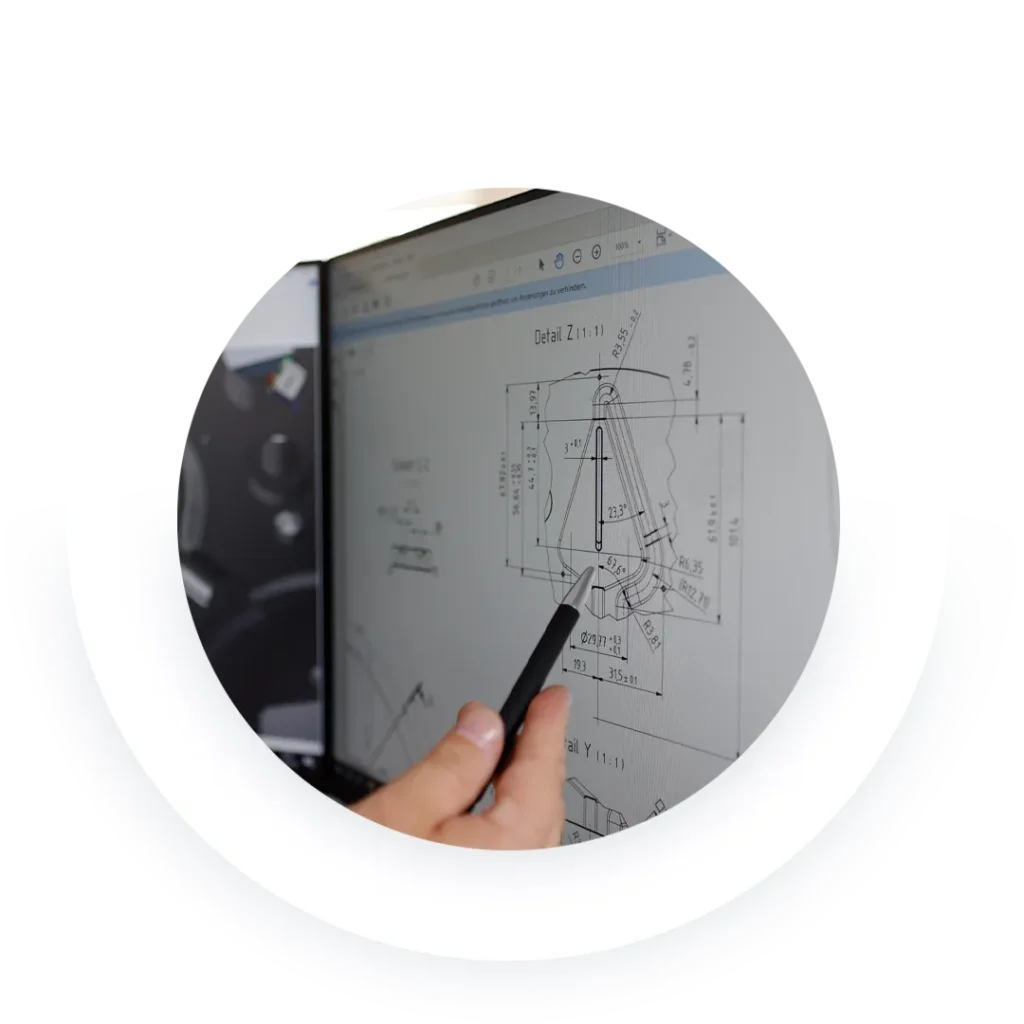

In many industries, the individual companies’ success relies heavily on parts or components which are made by CNC machines. These parts and components may be products for direct sale, parts for the performance of a certain service or a component needed for industrial production. There are almost unlimited potential uses for CNC milled or turned parts. The specific requirements for the components made by our company are always different, depending on customers’ needs. This is what makes our work so exciting – the entire process – from production planning and programming of the CNC parameters all the way to the final product.

If you want to know whether we can support you

in your industry, please contact us.

A broad spectrum of possible applications

Parts made by CNC machines have many advantages, which are equally interesting to various industries. This is especially true when it comes to precision, fit and finish – but also when repeatability and consistency of parts and components are priorities. Our main customer base operates in these industries:

Laboratory equipment

Für diverse labortechnische Arbeiten werden hochwertig gefertigte Bauteile und Komponenten benötigt. Dies können stabile Probenhalter, speziell geformte Gefäße, Gehäuse von Geräten oder auch Präzisionsteile für Messinstrumente sein. Gerade bei Analysen und Studien müssen die verwendeten Geräte und Hilfsmittel hochgradig konsistent produziert sein.

Optics technology

in the optical industry CNC parts and components have a myriad of uses and applications. They can be used in mechanical sub-groups of optical equipment, such as enclosures, holders, or frames for optics. Not only custom-made shapes are needed, but also precision-made threads for the assembly of modules for example.

Mechanical engineering

Mechanical engineering companies take advantage of CNC machined parts and components for applications, such as machine parts, drivetrains, control elements and tools. The high degree of CNC precision is essential for the perfect function of machines and equipment.

Tool making

CNC machining enables the manufacture of highly complex and precise tool geometries, which are needed to make other components in a highly precise and consistent way. Examples are dies, cutting tools or other specialized devices.