Measuring. Versatile. Accurate.

CNC-

measuring

In modern manufacturing, quality assurance plays a crucial role. At GDFT, we offer our customers the best possible product quality and rely on state-of-the-art technology.

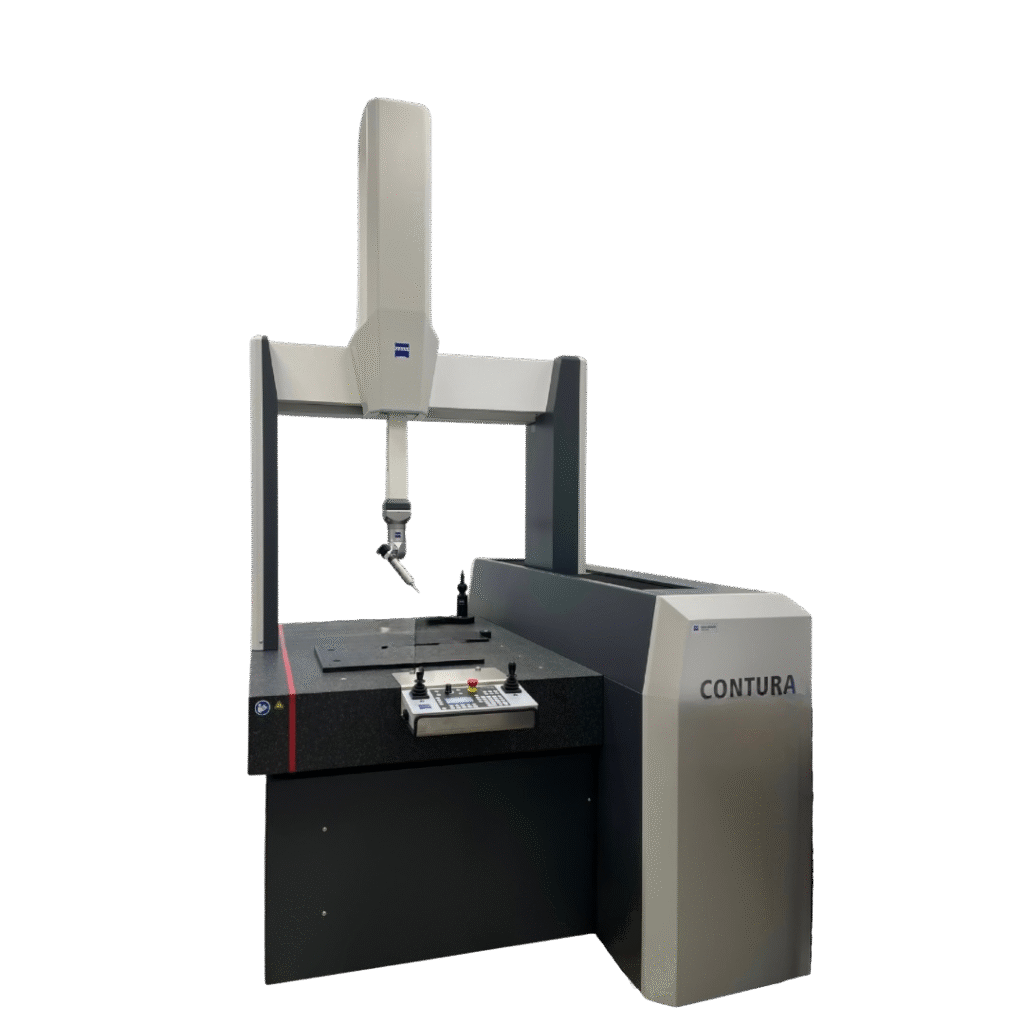

In 2024, we expanded our quality assurance by acquiring a coordinate measuring system (CMM): ZEISS portal measuring machine. This cutting-edge measuring device enables even more effective and reliable monitoring of our production processes. It helps us consistently meet the highest quality requirements and perform measurements with exceptionally high accuracy and speed.

Do you want to know if we can also meet your measurement requirements with our CNC measuring technology?

Measuring Accuracy at the Highest Level

A specially temperature-controlled measuring room was set up for the ZEISS CONTURA portal measuring machine, ensuring constant environmental conditions such as temperature and humidity. This stability is essential, as even the slightest fluctuations can affect measurement results.

At GDFT, the measurement process begins with the careful preparation of the components. Before inspection, they are cleaned and stored under optimal conditions to prevent deformation or contamination.

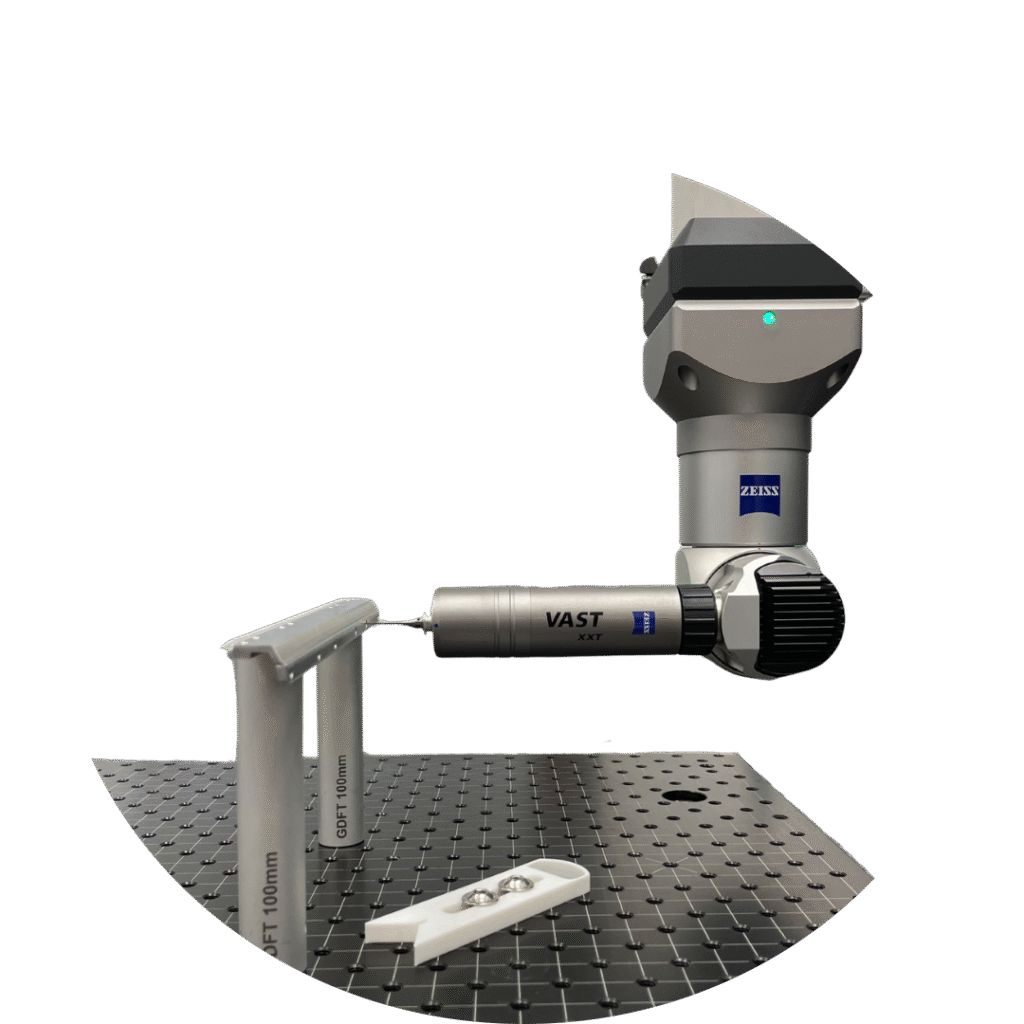

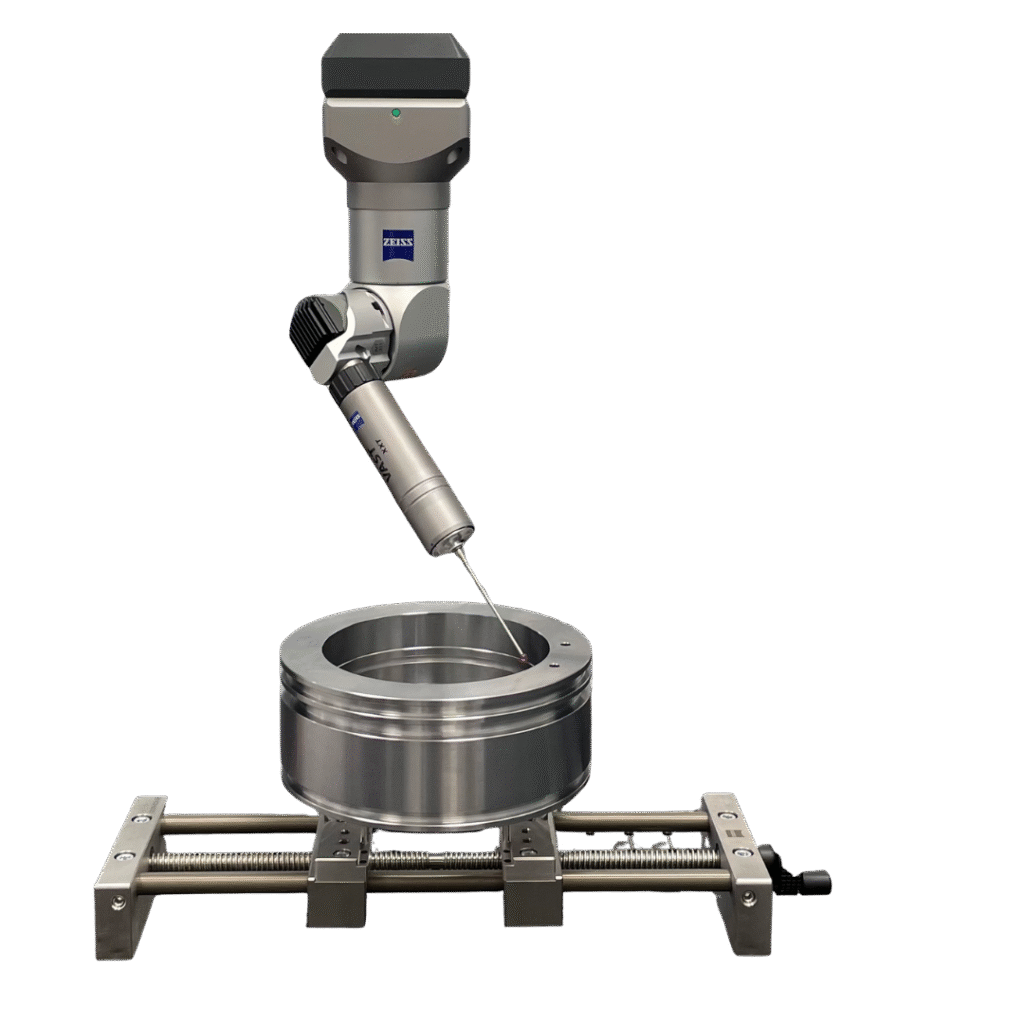

In addition to the CNC-controlled 5-axis coordinate measuring machine (ZEISS CONTURA), we also use a handheld CMM as well as various testing and measuring tools. This allows us to inspect components of a wide range of sizes and complexities flexibly and efficiently—from single parts to series production. The workpieces are precisely positioned on the measuring device and usually fixed with custom-made fixtures that allow repeatable, stress-free clamping.

After the measurement, all results are digitally documented, archived, and provided to the customer upon request. This ensures full traceability at any time—even over long periods.

We also store the measuring fixtures and clamping devices used with great care to ensure consistent conditions and maximum comparability for recurring inspections.

What is CNC-measuring?

CNC measuring is a computer-assisted measurement process used for the precise inspection of components. With modern coordinate measuring machines (CNC = Computerized Numerical Control), we check geometry, dimensions, and tolerances both during and after production.

Thanks to this technology, even complex components with the highest requirements can be inspected quickly and reliably. By using various testing and measuring tools, we ensure that every part meets the exact technical specifications.

- CNC measuring is a central part of our quality assurance—ensuring maximum precision and consistent product quality.

How the ZEISS portal measuring machine works

For maximum precision in quality assurance, we at GDFT rely on the ZEISS CONTURA 7/10/6 with RDS head (5-axis technology)—one of the leading portal measuring machines in industrial metrology.

The device features 5 axes, allowing measurements to be taken from various angles and ensuring the most precise analysis of components. It uses the X, Y, and Z axes as well as two additional rotary/tilting axes to measure the workpiece in different positions.

The measurement programs are created using a modern CAD-CAM system. The basis is the digital 3D model of the component, where all relevant measurement points are defined. Our AUKOM-certified metrology specialists program the entire process precisely and in compliance with standards—even for demanding measurement tasks.

- AUKOM certification: This internationally recognized training system confirms the solid expertise and practical competence of our metrology specialists in industrial measurement technology.

At GDFT, we preferably use SAT and SAB files for 3D-model programming. These file formats make it possible to import the 3D model directly into the measuring system.

Fakts CNC-measuring

ZEISS Portal Measuring Machine CONTURA 7/10/6 with RDS (5-axis)

Maximum travel X-axis: 700 mm

Maximum travel Y-axis: 1000 mm

Maximum travel Z-axis: 600 mm

ZEISS Portal Measuring Machine CONTURA 7/10/6 with RDS (5-axis)

Advantages of the ZEISS portal measuring machine at GDFT

- Early error detection: Thanks to the high precision, deviations are detected quickly, reducing scrap and lowering costs.

- High versatility: The measuring device is suitable for a wide range of components—from simple to complex shapes and even larger workpieces.

- Reliable accuracy: The 5-axis technology enables measurements from different angles, ensuring exceptionally precise results.

- Dependable quality assurance: Precise measurements help us meet strict quality requirements, increasing customer satisfaction and product safety.

- Comprehensive documentation: All measurement data is documented digitally and is transparent and traceable at any time.

Do you want to ensure that your product meets the highest metrological standards?